Standard 2MT Project background

In 1980 a small group of Bluebell Railway members paid a visit to Woodhams scrapyard in Barry, South Wales. Woodhams was one of the final resting places for the displaced steam engines of British Railways awaiting the breakers torch.

The visiting members decided to purchase a 2-6-0 No. 78059, a BR Class 2 Tender Engine that was minus its tender. A fund was set up to raise the £7,500.00 to buy the engine which arrived at the Bluebell on 23rd May 1983, as seen in Tony Sullivan’s photo on the right.

The lack of a tender and the fact that none of the 65 tender engines ran on Southern metals resulted in the decision being made to rebuild the engine as a tank engine. 30 engines were originally built with numbers 84020 to 84029 being allocated to the Southern Region based in the Eastern section for secondary duties mainly in Kent and East Sussex but none had survived into preservation. The decision to rebuild 78059 into a tank engine meant the next number in the series was taken out hence 84030 was born.

LMS & BR Class 2 Engines

The Class 2s were the smallest locos of the BR standard group of engines consisting of 60 tender and 30 tank engines. Both classes were based on the LMS (London Midland and Scottish Railway) Ivatt-designed locos, classified as 2MT (Class 2, Mixed Traffic) and destined to work on branch lines and secondary duties replacing a number of life expired engines.

The Ivatt-designed LMS Tanks had proven popular across Britain due to their wide route availability, ease of maintenance and efficient performance. The BR locos were a slightly heavier version of the Ivatts.

For interest 78059 was built at Darlington and released into traffic in September 1957 being allocated to Chester Northgate. After several moves it finished its working life at Crewe from where it was withdrawn in November 1966, a working life of just 9 years.

BR Class 2 Tank Engine Specification

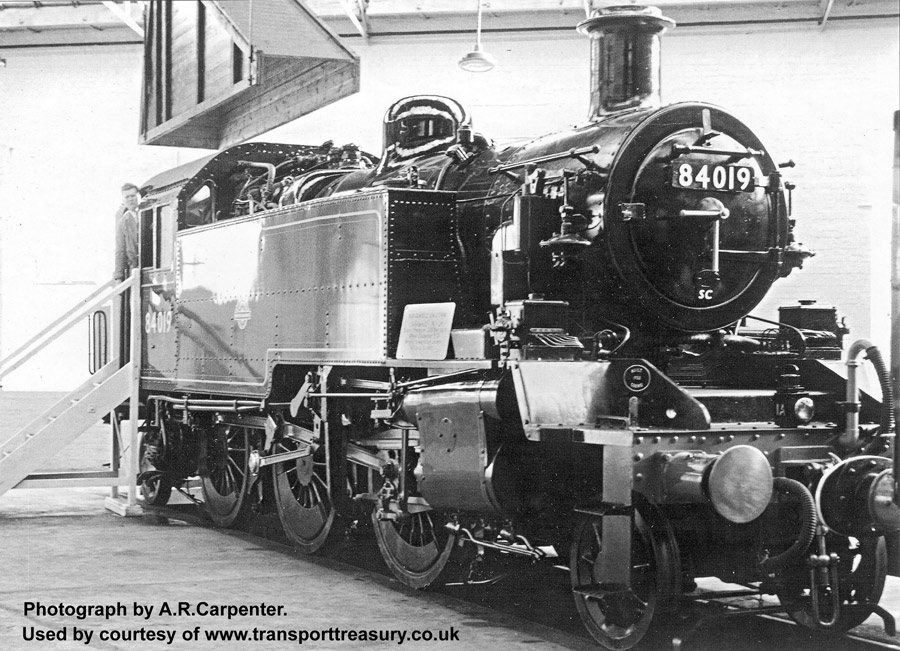

Thirty examples of the British Railways Standard Class 2MT 2-6-2 Tank locomotive were built; 84000-84019 at Crewe Works in 1953 and 84020-84029 at Darlington Works in 1957. They were all due to be built between 1952 and 1953 but the steel shortage in Britain’s post-war economy caused a cut-back in the locomotive building programme to be implemented early in 1952. This resulted in the first of the class being outshopped in August 1953, 12 months behind the original schedule, and the Darlington locomotives being deferred for several years. The first 20 were designed for use on the London Midland Region, whilst the 10 Darlington-built engines were delivered to the Southern Region.

Technical Data

Class: Standard Class 2 No. 84030 – as being rebuilt

Wheels: 2-6-2T

Class introduced: 1953

Designer: R.A. Riddles (but based closely on the LMS Ivatt design)

Purpose: Light Mixed Traffic on cross-country routes

Total number built: 30 (this will be the 31st)

Length: 38ft 9.5in overall

Weight: 66 Tons 5 cwt

Water capacity: 1,350 Gallons

Coal capacity: 3 Tons

Boiler Pressure: 200 lb/sq.in

Driving Wheels: 5ft diameter

Pony and Trailing Wheels: 3 ft

Cylinders: (2, outside) 16.5″ x 24″

Tractive Effort: 18,515 lbs

BR power classification: 2MT – or 2P/2FA on BR(S)

Rebuild project

After arrival at the Bluebell Railway some work was started on the loco but the main effort for a good length of time was to raise funds to repay the money loaned to the group to cover the cost of transport from Barry. Eventually the boiler was taken out and stored on a flat wagon and the frame was lifted from the wheel sets, these were cleaned and sent to Swindon for turning, returning to the Bluebell during March 1991.

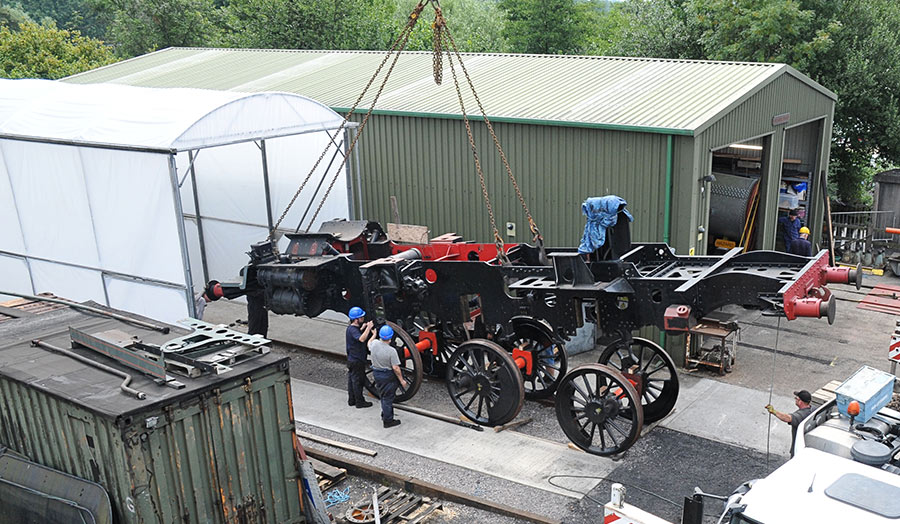

A little while after the wheels were returned to the railway Colin Turner recruited Stan Ponting and John Jesson to work on the project and a small group was formed who met regularly on Thursdays. The next major step was to cut off the rear section of the frames and weld on the newly constructed rear frame extension, the engine finally becoming a tank engine, this work was completed by the workshop staff during 2011.

The next big stage was to construct a hard, covered and level standing area as the engine had been stored in a number of locations all being outdoors and open to the elements other than a short period in the running shed. This made working on the engine difficult and very much weather dependent plus a continuous battle to protect the engine from the British weather.

The problem was finally overcome when in 2018 hardstanding was created, with a poly-tunnel style building erected over it, alongside Atlantic House. The opportunity was taken to reunite the frames with its driving wheelsets when relocating the engine into its new dry home.

In between these major stages, work has continued on a large number of items such as front and rear pony trucks, horn guides, sanding valves, vacuum and steam pipework plus a large number of valves, springs, fittings etc. A lot of this work was recorded in John Jesson’s 25 newsletters published between Spring 2006 and Summer 2018 and in the regularly published Bluebell News magazine.

Since the untimely death of John, who with Stan Ponting led the team working on the project for over 12 years, a new team has been formed led by Chris Wren and Brian Turner. Tony Sullivan, who was in the party that visited Woodham’s scrap yard in Barry and was instrumental in securing the engine for the Bluebell, is still a keen member of the working group looking after all the funds and administration.

Current news

July 2024

Work has progressed on the bunker with all panels in their final position, majority of rivets fitted, and the welded seams started which are extensive and will keep us very busy for quite some time.

January 2024

The righthand side of the bunker now in position and ready for welding, and then the drilling and riveting of the angle iron strengthening bars.

It is planned for the bunker to be complete by this summer and then a start will be made on the cab.

July 2023

One of the new tanks, constructed to our drawings by the 4253 Loco Group based at the K&ESR, delivered to Sheffield Park on 18 July.

January 2023

The new right-hand side tank which has been constructed off-site.

October 2022

The rear bunker panel in its final position and bolted down to the underframe.

April 2022

The new steel plate which has been profiled and delivered which will form the front and rear of the bunker. The refurbished and re-certificated lifting gantry, which will be put to good use in erecting the bunker onto the engine frame.

December 2021

The (extended) rear frame of the locomotive, onto which the new bunker, now under construction, will be assembled.

September 2021

The start of assembling the new bunker – this is the shovelling plate. The profile-cut holes in the plates are being used as a template for drilling the angle iron. The assembly is then temporarily bolted together for trial fitting in its final location before drilling/reaming for riveting.

July 2021

The team have recently returned to work on the project. We are appealing for new volunteers to join the project, since not all the old team have returned after the lockdown.

Spring/Summer 2020

The project came to a halt due to the Coronavirus pandemic and the enforced shutdown of the railway. This has not meant that nothing is happening as Harry, an apprentice in the Loco Works, is preparing manufacturing drawings for the side tanks. This is proving to be a difficult exercise and very time consuming but hopefully Harry will have the drawings in a position that cost estimates can be obtained once we are all back at the Railway. In addition Vic Short, a volunteer in the Carriage and Wagon Department at Horsted Keynes, has been producing a number of CAD drawings, from information supplied by Brian Turner, suitable for laser or water jet profiling of components for the side tanks, sanding valves, hand brake and bunker.