By the end of Monday 26th February, all of the new rails were in place. There is still plenty to do with ballasting and tamping to be done.

The sleepers are stacked to the side of the formation prior to the relay in stacks of 8 or 16. When required they are moved 4 at a time using a bar which has 8 lugs which fit the eyes on the sleepers. The sleepers are then craned over onto the prepared formation. As the rail has not yet been laid, a tracked crane is required rather for this than a road-rail vehicle. The sleepers are swung round into position. Wooden spacers are use to correctly distance the sleepers from each other and the marked line denotes the position of the sleeper ends. Even so, a degree of fettling with a bar is needed to get the positions close to their final position. The rails are lifted in as can be seen from the previous entry.

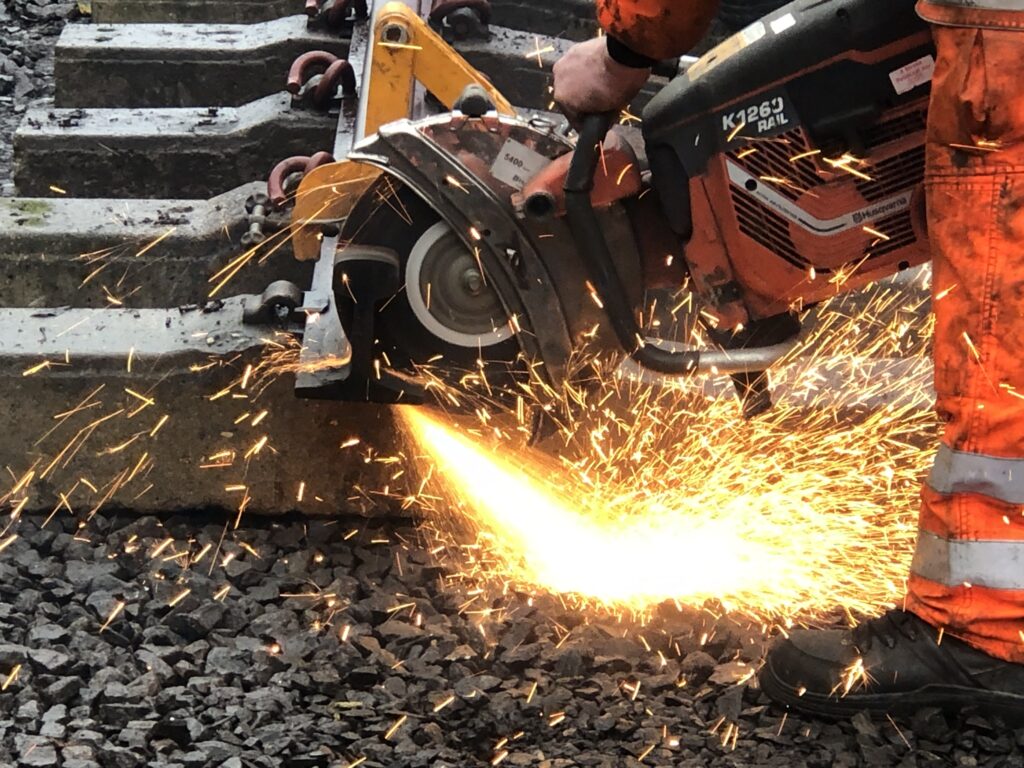

As the rails are being craned in, the pandrol track clips and insulators a re laid out. We are laying track on a curve so while the outside rail is full length, the inner rail needs to be cut with the rail saw.

The outer rails had the fishplate holes drilled in advance of the relay but because of the curve and the requirement to cut the inner rail to length, one pair of holes are drilled in situ. The Milwaukee electric drive is used to tighten fishplate bolts. In the image on the right, the setter (blue tool on the right) is used to position the sleeper laterally and provide any lift needed to bring the sleeper up to the rail. The setter is not required for every pair of clips. The tool on the left is a puller which draws the pandrol clip into place.

The rail has been relayed from the north. At the south end, the rail now meets to old 96 pound bullhead. As can be seen, there is a considerable difference in the shape of the rail and special junction plates are required. These can be seen lying on the sleeper end. What cannot be judged is the difference in wear between the new flat bottomed rail and the old rail. This leads to a step in height at the rail head. There are a variety of junction plates which allow for this and bring the railheads level. Needless to say that the junction plates we initially brought along did not have the correct step. This will be easily rectified the next day.

Images: Jon Goff, Mike Hopps and Bruce Healey